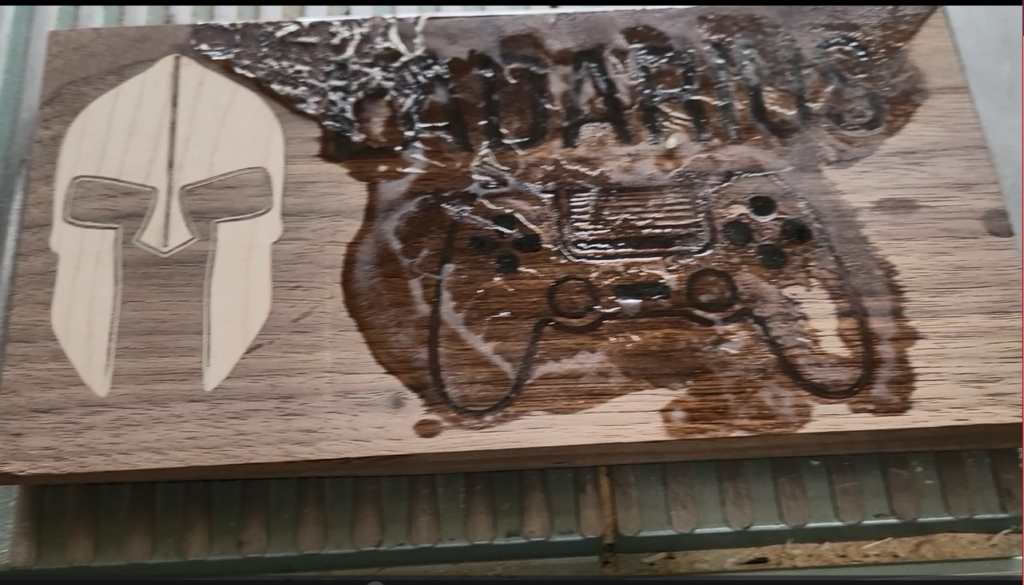

Introduction: In this captivating video, I share my journey of exploring the world of CNC during the winter season. With the arrival of my CNC machine in early January, I dedicated nearly three weeks to acquaint myself with various toolpaths and different bits. This particular video focuses on my first real v-carving project, where I aimed to create a special plaque adorned with my grandson’s name, a game controller, and a Spartan mask. Little did I know that this project would teach me valuable lessons about the intricacies of epoxy inlay and the importance of temperature control.

The Perfect Spartan Mask and the Chipped Words: As I embarked on this project, my enthusiasm soared. The Spartan mask v-carve turned out flawlessly, exceeding my expectations. However, when it came to the lettering, I encountered some chipping issues. Determined to rectify the situation, I decided to re-carve the letters, inadvertently sparking the idea of incorporating epoxy inlay for both the game controller and my grandson’s name. Excited by the prospect, I forged ahead, unaware of the temperature-related challenges lying ahead.

The Perfect Spartan Mask and the Chipped Words: As I embarked on this project, my enthusiasm soared. The Spartan mask v-carve turned out flawlessly, exceeding my expectations. However, when it came to the lettering, I encountered some chipping issues. Determined to rectify the situation, I decided to re-carve the letters, inadvertently sparking the idea of incorporating epoxy inlay for both the game controller and my grandson’s name. Excited by the prospect, I forged ahead, unaware of the temperature-related challenges lying ahead.

Epoxy Inlay Challenges in Winter:

Epoxy Inlay Challenges in Winter: With winter’s icy grip tightening, I began the epoxy inlay process. Regrettably, like many others, I skimmed through the instructions without fully grasping the significance of temperature. It escaped my attention that epoxy should be at, or above, room temperature during application, and the curing process should occur in a similar environment. As the video shows, my otherwise perfect plaque turned into a gelatinous mess, leading to a frustrating three-week ordeal of unsuccessful drying and curing attempts.

Discovering the Importance of Temperature Control: After weeks of disappointment, I delved deeper into epoxy inlay troubleshooting and stumbled upon a crucial revelation. Once epoxy reaches a gelatinous state, it is irreversible and will never solidify. Frustrated but determined, I resolved to learn from this experience and make a new plaque for my grandson.

Lessons Learned and Moving Forward: The foremost lesson gleaned from this endeavor was to never attempt epoxy inlay in cold weather conditions, especially below 60 to 73°F (15 to 23°C). Warmth plays a pivotal role in the successful curing of epoxy. It is a lesson I won’t soon forget. As the saying goes, “Education is the key to success,” and this experience reinforced the importance of continuous learning.

A New Plaque, A Fresh Start: Undeterred by the setback, I embarked on crafting a new plaque for my grandson. Surprisingly, he revealed that he preferred the new design without the epoxy inlay. With colors filling the engraved areas, the new plaque dried beautifully, highlighting the value of flexibility and adaptation in creative projects.

Conclusion: Join me in reflecting on my winter v-carving adventures and the valuable lessons learned through my epoxy inlay misadventure. As we embark on our own creative endeavors, let us always remember to educate ourselves and remain adaptable. Thank you for watching the video and reading this post. I look forward to hearing your stories of projects gone awry and sharing our collective experiences. Don’t forget to leave a comment and stay tuned for more exciting posts in the future.